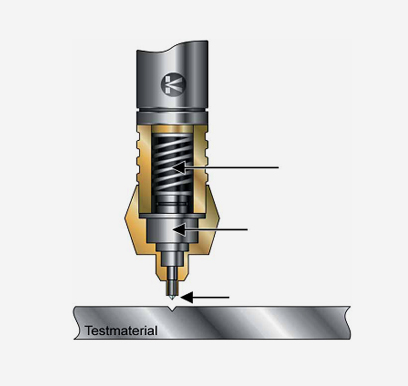

Many Codes and specifications specify Hardness Testing of Materials in the field after such activities as oxyacetylene cutting, cold bending, post weld heat treatment etc. AEIS can provide on-site hardness testing services utilizing portable instruments such as:

- AMES Portable Rockwell Hardness Tester

- GE MIC 10 and MIC 20 UCI tester

- Proceq Leeb Hardness Tester

In addition to the surface preparation specified by the equipment manufacturer, some materials such as Creep-Strength enhanced Ferritic Steels (CSEF) require special attention. For P91 Alloy, hardness values after local PWHT are usually specified between 200 to 275 BHN. Hardness below 175 BHN is an indication of overheating of the joint (above AC1) and may require replacement OR Normalize/ Temper treatment of the entire assembly. However, if the decarburized layer on the surface is not removed by grinding, the test may show “false” lower values. AEIS personnel have the necessary experience and expertise to perform your field hardness testing.

ASTM A956 - 06 Standard Test Method for Leeb Hardness Testing of Steel Products

ASTM A1038 - 08 Standard Practice for Portable Hardness Testing by the Ultrasonic Contact Impedance Method

Let’s Connect

NDT. Non-Destructive Testing. That’s our Core Business. That is our Only Business. We live it, We breathe it. We are dedicated to it. Let us use NDT to take your business to new heights.