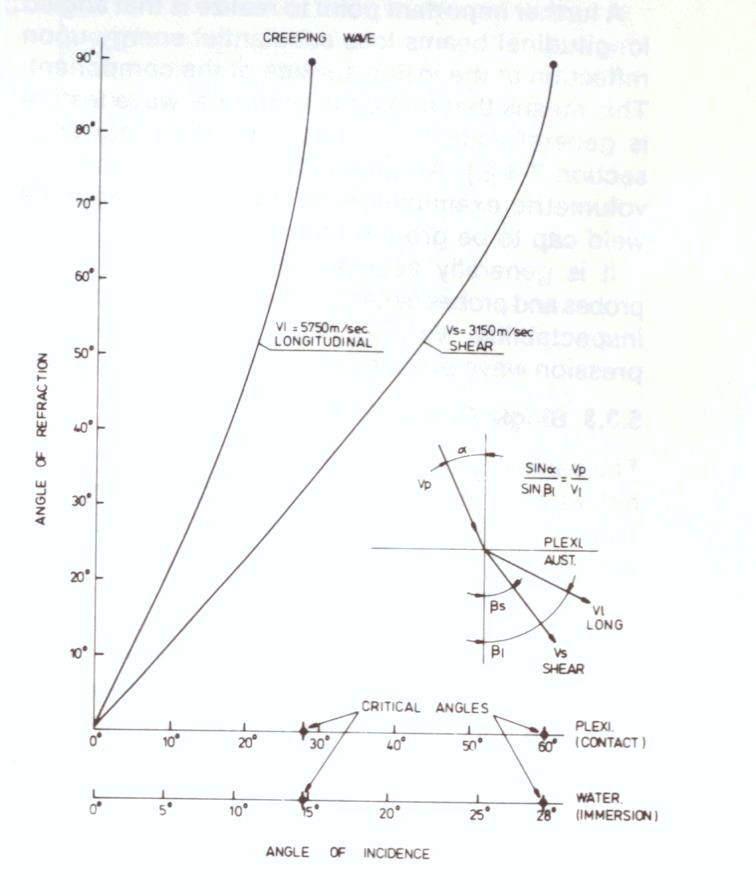

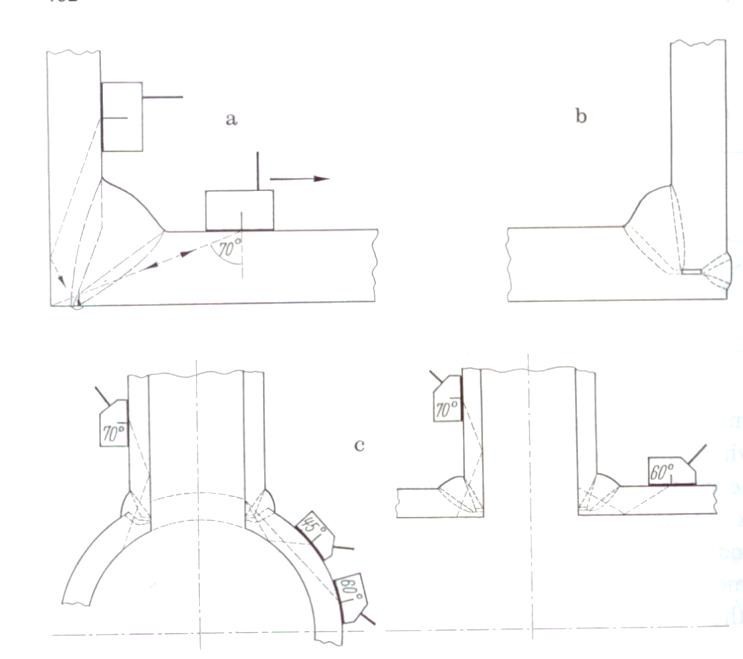

Ultrasonic Testing utilizes sound waves with a frequency greater than 20 kHz (inaudible to humans) to detect flaws and/ or material properties. Energy source is usually a “piezoelectric transducer/ probe” which provides a vibration response on an oscilloscope trace. Interpretation is comparative, based on calibrated responses from known size flaws in acoustically similar material.

Ultrasonic testing has a very wide scope for materials testing. Modern Ultrasonic Testing (UT) can be utilized for finding cracks, de-bonds and laminations; detecting macrostructure variations and anomalies; variations in physical dimensions; and for density, mass and elastic property determinations. Ultrasonic testing can be performed on metals, nonmetals and composites.

One of the crucial elements in Ultrasonic testing is utilization of “acoustically similar calibration and reference standards”. AEIS has a very large inventory of calibration and reference standards. We strive to add to our inventory as more new and complex components are provided to us for testing.

Ultrasonic Testing can be utilized to detect flaws up to 0.01 mm in size using pulse-echo technique.

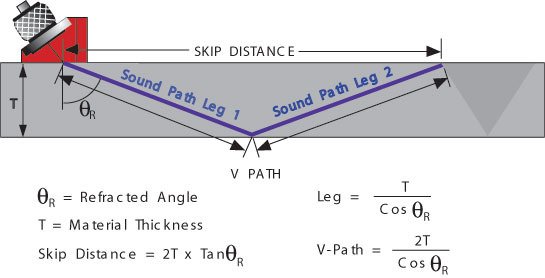

Film Image Showing Shound Path Skip Distance

Some of the standards utilized at AEIS for Ultrasonic Testing are ASTM E-2223, E-214, E-797, E-494, E-587, E-164, E-213, E-1315, E-2375, E-273, E-114, E-2373, E-1901.

Our field engineers and technicians utilize state-of-art portable flaw detectors like Olympus Omniscan phased array UT and GE USN 58L with electronic distance amplitude correction (DAC)/ Time corrected gains (TCG). We have a huge selection of probes available from 0.5 MHz to 20 MHz; from pencil probes for evaluation on pitted surfaces to large diameter high energy probes for highly attenuation materials.

Our personnel are experienced in performing ultrasonic testing for different industrial segments including aerospace, automotive, railroad, construction, consumer products, defense, manufacturing, marine, power & utilities, refineries and petrochemical plants. Our diversified experience includes ultrasonic testing of billets to welds on bridges to composites for defense submarines.

Let’s Connect

NDT. Non-Destructive Testing. That’s our Core Business. That is our Only Business. We live it, We breathe it. We are dedicated to it. Let us use NDT to take your business to new heights.