Since the discovery of X-Rays by Professor W. C. Röntgen on November 8th 1885, radiography has made a lot of strides. In addition to the development of X-Ray machines and Gamma Radiography devices, the imaging sensors have also improved tremendously. From imaging on a barium platinocynide paper to film radiography to the modern film-less digital imaging, the science has improved tremendously, facilitating very high resolution images that can be further enhanced using specialized digital software.

The principles of radiography are relatively simple:

The X-Ray machine or Gamma Radiation is the source of the rays and transmits penetrating X or Gamma Rays. The object being radiographed partially absorbs these rays. In areas where there are flaws or breaks, a greater or smaller number of rays are able to penetrate.

Because X and Gamma Rays are invisible, a detecting agent is required to produce a visible picture. This detecting agent can be the radiographic film in light proof wrapping or a Digital image sensor. The areas where the film/ sensor has been exposed to more rays show up dark when developed.

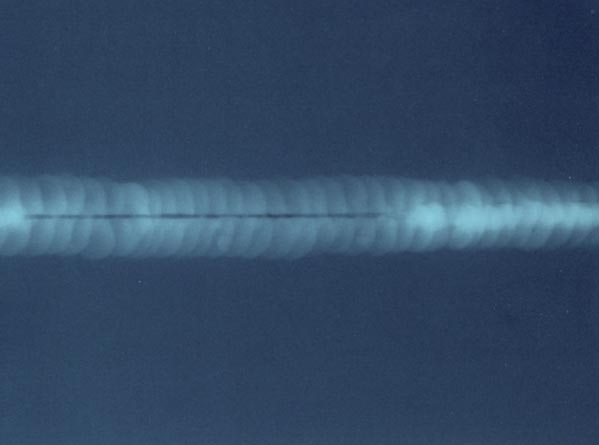

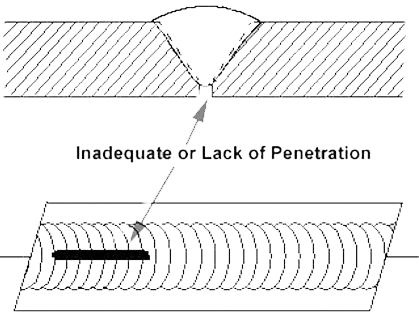

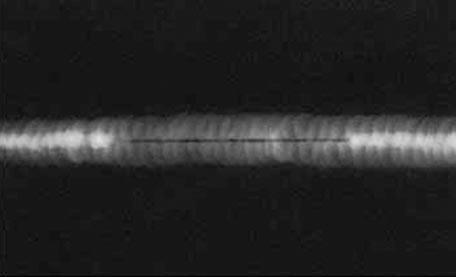

In the example shown here, a lack of root penetration in a weld is pictured. In the area of lack of penetration, more rays pass through the metal compared to the adjacent areas and so show up as a darker image on the developed film.

AEIS can perform industrial radiography on a very large variety of materials from metals, plastics, PVC, rubber, composites and concrete. We are ISO 17025 compliant for performing NDT and our personnel have ASNT/ ACCP NDT Level III and Level II certifications in Radiographic Testing.

Film Image showing Shrinkage in a Casting

Gamma Radiographic Testing can be utilized to detect density or thickness variation up to 2 percent of the material thickness under evaluation. Some of the standards utilized at AEIS for Radiographic Testing are ASTM E-1030, E-1032, E-1161, E-1079, E-1817, E-801, E-2104, E-1742, E-1734, E-999, 1390, E-94, E-1254, E-689, E-1648, E-802, E-186, E-280, E-272, E-155, E-505, E-446, E-390, E-431.

We maintain a complete updated library and understanding of all relevant major codes such as ASME Section I, V, VIII Div 1/ 2, IX, B31.1, B31.3; API 620, 650, 1104; AWS D1.1, 1.2, 1.3, 1.4, 1.5, 1.6, Indian Boiler Regulations, NYSSCM.

With X-ray equipment, Ir-192 and Co-60 available for field radiography, we can image a very wide range of thicknesses in a variety of materials. Our crews are available for both routine radiography and planned/ emergency shut-down work.

Let’s Connect

NDT. Non-Destructive Testing. That’s our Core Business. That is our Only Business. We live it, We breathe it. We are dedicated to it. Let us use NDT to take your business to new heights.