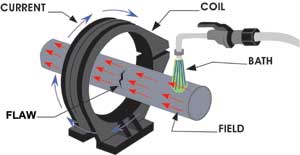

Magnetic particle Testing (MT) is a nondestructive method which utilizes the flux leakage arising as a result of surface and near surface discontinuities to detect flaws. A Magnetic current or field is imposed on the part under inspection, a flux leakage at the surface of the part results in accumulation of sprayed iron powder, giving a direct indication of flaw.

Magnetic Particle Testing can be utilized on any ferromagnetic material in a variety of forms such as bars, forgings, weldments, extrusions, fasteners, engine components, shafts and gears to detect inherent, primary processing and in-service discontinuities. Examples of detectable discontinuities are:

Inherent: Cold Shut, Pipe, Hot Tears, Porosity, Inclusions and Segregation in Castings.

Primary processing: Seams, Laminations, Stringers, Cupping, Cooling Cracks, Laps, Bursts and Hydrogen flakes formed during various forming operations. Welding discontinuities such as Cold cracking, Hot cracking, Lamellar tearing, Lack of fusion, Lack of penetration, porosity, inclusions (Slag, Tungsten, Oxide), Undercut and Overlap. Cracks and tears developed during operations such as Heat treating and quenching, pickling, machining, and plating.

In-service Discontinuities: Cracking associated with phenomenon such as Fatigue, Creep, Stress Corrosion, and Hydrogen embrittlement.

Film Image Showing Magnetic Particle Testing

Magnetic Particle Testing can be utilized to detect cracks to 0.5 mm in major dimension. Some of the standards utilized at AEIS for Magnetic Particle Testing are ASTM E-125, E-709, E-1444, E-2297.

AEIS possesses state-of-art portable equipment for field operations as well as Large Wet Magnetizing and Demagnetizing Benches for Magnetic Particle testing. We perform MT utilizing dry powder, wet suspended particles with visible as well as fluorescent materials under Ultraviolet light. All inspections are performed by Level II certified technicians with extensive experience. All work is monitored by NDT Level III in Magnetic Particle Testing.

Our personnel have successfully performed magnetic particle inspections for the aerospace, automotive, railroad, construction, defense, manufacturing, marine, power, utilities, refineries and petrochemical industries. AEIS has inspected fasteners, hardware, engine components, gun components, impact damage and repairs on bridges, pipe welds and various structural weldments utilizing Magnetic Particle Testing.

Let’s Connect

NDT. Non-Destructive Testing. That’s our Core Business. That is our Only Business. We live it, We breathe it. We are dedicated to it. Let us use NDT to take your business to new heights.